Woodwork For Inventor Vs Wood. Experience, permanent work with furniture manufactures and deep knowledge of. Woodwork for Inventor eliminates this gap and makes Autodesk Inventor powerful tool for woodwork professionals.

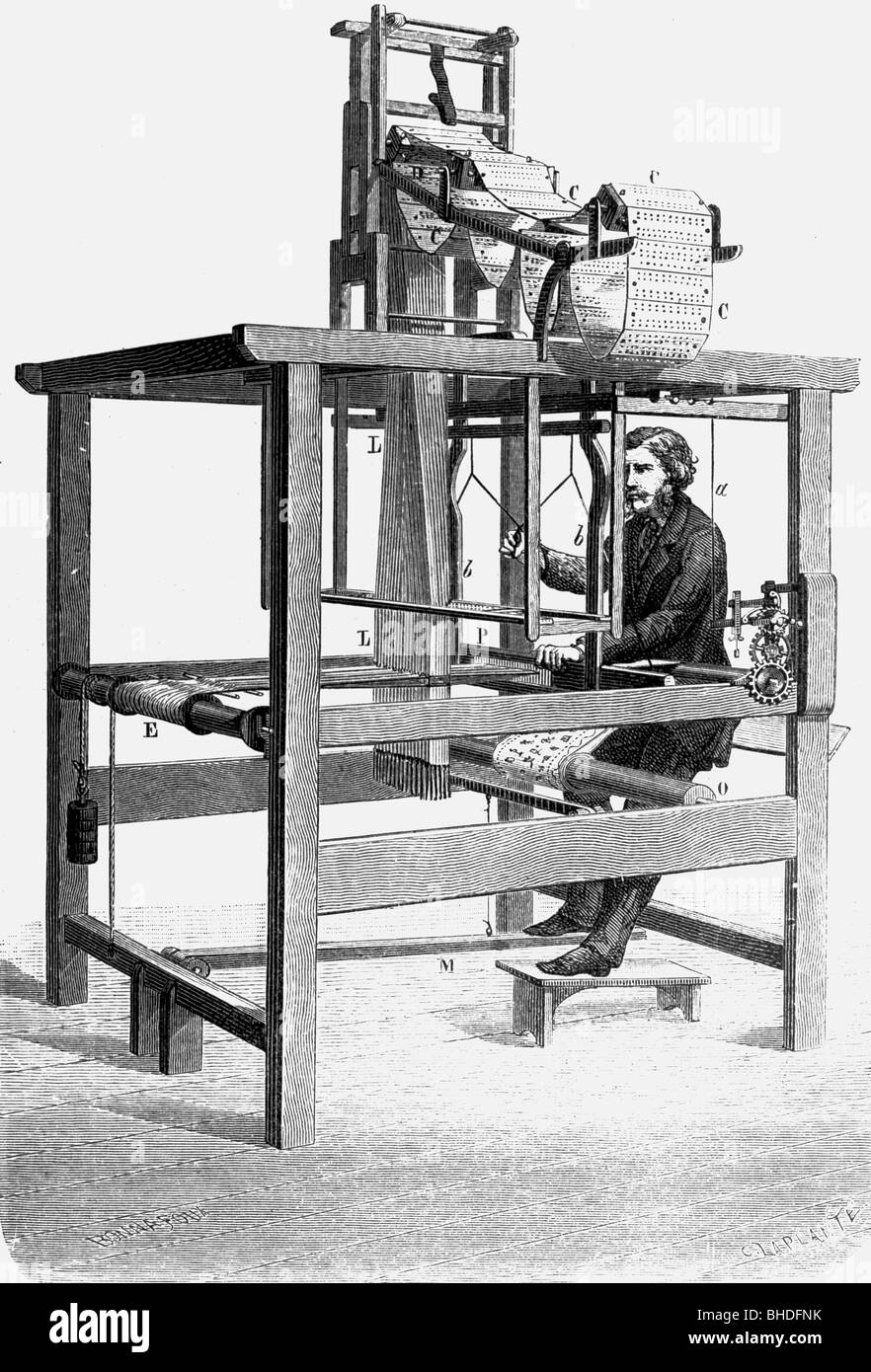

Woodwork For Inventor Vs Wood The drawing is the foundation for the final result.

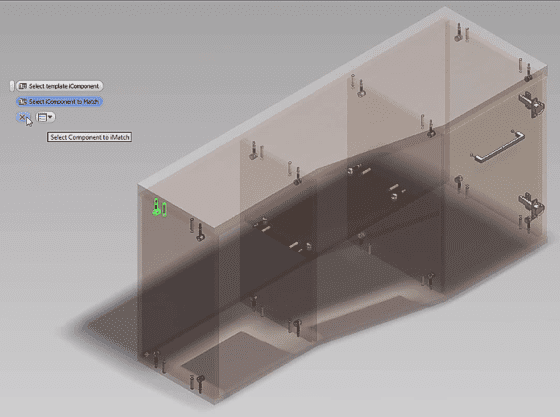

However, Woodwork for Inventor recently added their own CNC / Nesting solution. Woodwork For Inventor Vs Wood.

I disagree that machining wood vs. metal is easier. An operative editor for multi-layer materials has been introduced.

Set installation path for add-on and click "Next". Woodwork For Inventor Vs Wood Once you start Autodesk Inventor, you will see a "Woodwork Design" tab on the menu bar.

Woodwork For Inventor Vs Wood The grain configuration of wood, it's phisical properties and differences even within the same piece of lumber make it hard to.

Both Woodwork for Inventor and Woodwork for Inventor with CAM licensing model is a Permanent license plus Maintenance plan. For industrial design, Autodesk Inventor has both B-Rep and T-Splines surfacing, while Solidworks leverages more on B-Rep surfacing and has some nice tools within this module. The best thing about Woodwork for Inventor software is that it is user-friendly and can be used by anyone. An operative editor for multi-layer materials has been introduced. Top solid wood is best in this field due to its integrated cam and all wood joinery operations like tenon-mortise,nesting and all hardware application. would suggest top solid wood for any wood based manufacturing. However, it can successfully meet the residential and commercial furniture design requirements. Follow the steps in the installation guide, install the files.Create Beautiful Woodwork With Woodwork for Inventor. Woodwork For Inventor Vs Wood.

0 comments:

Post a Comment